Load items are manually entered into the application during the survey. The time savings comes on the backend since the data are directly imported from the application. This process eliminates a data-entry step, and normalizes the data as you proceed. Handwriting is not an issue, the app record who does what and when. Staffing for survey teams can be adjusted on the fly, instead of at the end of the day once all data sheets are entered.

Learn More - Contact US!

A new data architecture has been implemented based on semantic web technologies and ongoing research conducted by Praeses Business Technologies with the Air Force Research Laboratory (AFRL). Data from both the upstream sources and weight surveys can be captured in an innovative, yet proven, Resource Description Framework (RDF) Triplestore format for reuse or expansion to include additional datasets. RDF Triplestores can be used to store the data from a number of different sources and structures while maintaining both the original and new relationships between the different elements.The data collected can be repurposed to support compartment closeout, systems certification, or monitoring of construction status.

Learn More - Contact US!ShipSurveyorXT is implemented at your shipyard — deployed as a production version of the system in your environments or in a cloud-hosted

environment depending on shipyard security rules and preferences.The application will include the administrative capabilities to enable you to fully manage the process yourself. Praeses Business Technologies provides ongoing support and maintenance of the system through a support contract.

The implementation of ShipSurveyorXT will provide benefits to your shipyard and customers (Navy, Coast Guard, certification, or commercial entities) by modernizing an often overlooked but critical aspect of ship construction, operation, and lifecycle support.

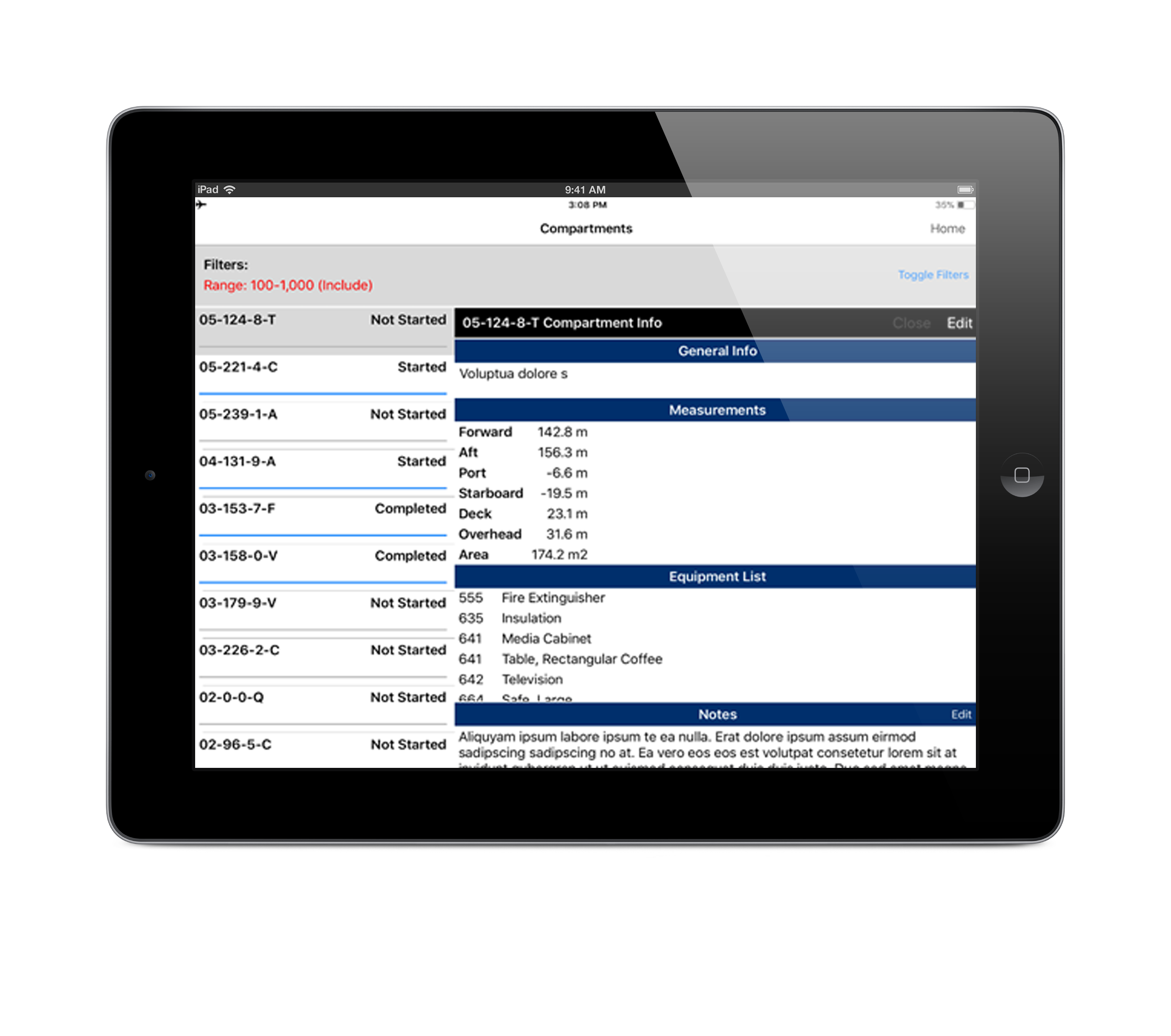

The current version supports surveys by multiple survey teams, who are assigned compartments to survey by a supervisor using a web-based system. ShipSurveyorXT currently runs on an iPad Air that can work in a disconnected state while conducting shipboard surveys. For each assigned compartment all items, their weights, and their centers of gravity relative to a pre-defined bulkhead are contained in the database on the tablet device. The team conducts the survey which includes: moving items that are misplaced, identifying weights that need to be added (common items such as forklifts, welding machines, etc.), identifying weights to be subtracted (items not installed), creating notes, taking photo documentation, and closing out the compartment.

At the end of the day or as soon as the tablet is able to connect to a network, the team member’s survey data will be uploaded to the server where the data is available on the web application for further modification and eventually for creation of the weight report.